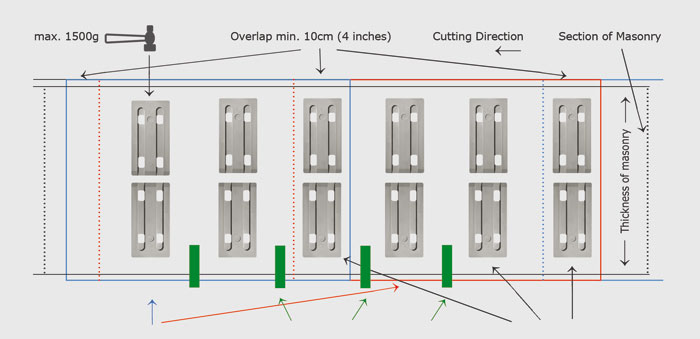

Instructions for retroactively installed horizontal insulation using the saw method and placement instructions for the placement of insulating foil and masonry wedges.

The cut is performed, using a carbine-tipped chain saw or a diamond wire saw in sections of max. 1 m (40 inches) length. In some cases, if the wall structure is very loose or jagged, a shorter cut is necessary. Prior to any cutting, pipes or wiring inside the wall must be located, any plaster or joints in the area of the cut must be removed (it reduces wear and increases working speed). When applying the foil and wedges, the cutting must be stopped and as a safety precaution, the saw must be shut off.